Defects are a natural result of mass production and industrialization, though customer satisfaction is built on reliable defect free products. Currently destructive testing is the main quality control measure to capture defects which is labor intensive, wasteful, and randomized. IR4TD believes that Real time Automated Non Destructive Testing (NDT) can be the best measure to insure that ALL products are defect free on the surface and the subsurface. also new generation of smart Non Destructive Evaluation (NDE) systems can be used to evaluate and identify the defect characterization and point of origin. Such knowledge will provide a data system for preventive maintenance practices, rework, and product and process development.

At IR4TD we have the expertise to develop NDE vision systems based on:

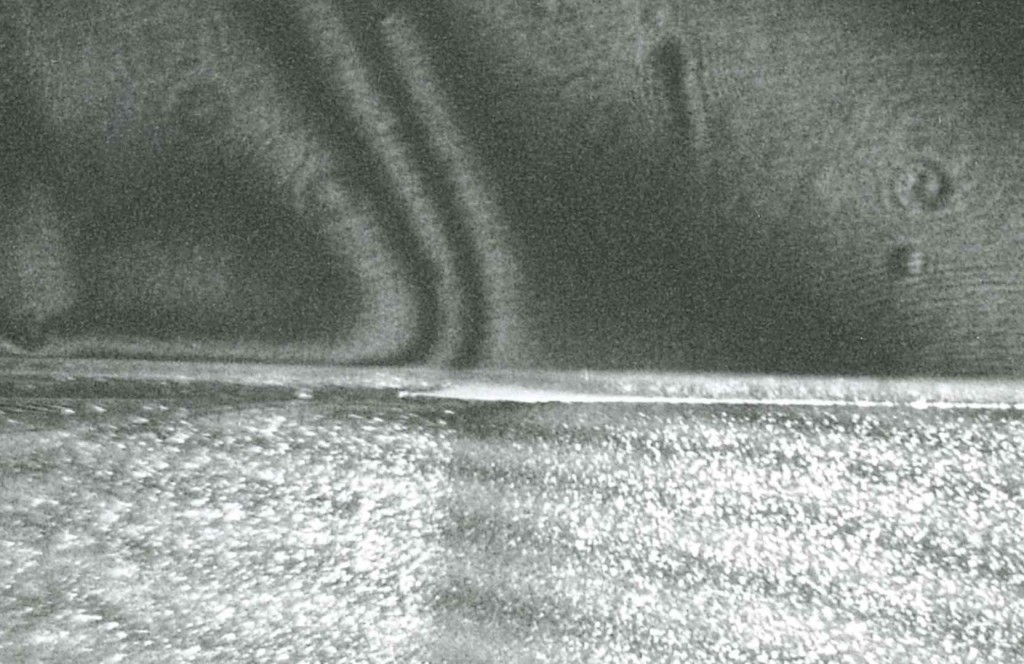

IR4TD researchers are capable of doing holographic interferometry. In double-exposure holographic interferometry an interference pattern between two reconstructed images of the same object. A holographic recording is first made with the object in some reference state. The object is then moved or deformed as desired, and a second hologram is made on the same photographic film. During reconstruction two waves are created and interfere in the space beyond the hologram. The resulting interference fringes record the local displacement of the surface of the object.

IR4TD researchers are capable of doing holographic interferometry. In double-exposure holographic interferometry an interference pattern between two reconstructed images of the same object. A holographic recording is first made with the object in some reference state. The object is then moved or deformed as desired, and a second hologram is made on the same photographic film. During reconstruction two waves are created and interfere in the space beyond the hologram. The resulting interference fringes record the local displacement of the surface of the object.

For more information contact us.

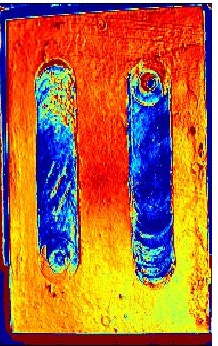

Infrared thermography or infrared imaging extends our knowledge and intuition by seeing the unseen. Infrared detectors measure infrared radiation emitted or absorbed within a field of view and infrared thermography technology converts this information into thermal maps. By studying these thermal maps both in space and time it is possible to identify and understand the origin and type of surface and subsurface defects. Hence, infrared thermography is a noninvasive method that does not require contact with an object under examination. It is an immensely useful and quantitative technique having flexibility to be applied under diverse stimulation sources and durations that can maximize detector sensitivities and relationships between the stimulation source, the specimen and the detector.

Infrared thermography or infrared imaging extends our knowledge and intuition by seeing the unseen. Infrared detectors measure infrared radiation emitted or absorbed within a field of view and infrared thermography technology converts this information into thermal maps. By studying these thermal maps both in space and time it is possible to identify and understand the origin and type of surface and subsurface defects. Hence, infrared thermography is a noninvasive method that does not require contact with an object under examination. It is an immensely useful and quantitative technique having flexibility to be applied under diverse stimulation sources and durations that can maximize detector sensitivities and relationships between the stimulation source, the specimen and the detector.

At the IR4TD, infrared thermography initiatives include research and development to:

- Develop new quantitative infrared thermography techniques

- Develop new methods that can see deeper into specimens

- Optimize detection and excitation parameters to deliver the best solution for inspection processes and systems

Specific areas of development include:

- Novel selective heating regimes such as infrared heaters, ultrasonic, radio frequency, microwave and ultraviolet

- Novel image processing techniques

- Basic understanding of heat wave propagation in materials

- Basic understanding of materials optical and physical properties and their effect on thermal imaging

For more information please contact us.

Visual imaging is known to be the simplest form of nondestructive testing and evaluation. At the IR4TD, visual imaging is used to:

Visual imaging is known to be the simplest form of nondestructive testing and evaluation. At the IR4TD, visual imaging is used to:

- Develop new quantitative techniques;

- Develop new image processing methods;

- Develop image fusion techniques.

For more information please contact us.

The system compromise of hardware and software that include in house image processors and filters that will result in user friendly interface. The system will be developed based on the physics associated with the process understudy, the nature of the defects, and practicability meeting the needs and detection criteria of the client.

For further discussion please contact us.